In our article on Planned Obsolescence, we address the tension between the growth model of the modern economic system and ecological limits, starting from the basic framework of the concept of sustainability. Positioning planned obsolescence as the system’s self-sustaining strategy, we examine short-lived production policies in the textile sector, using polyester as an example. By differentiating between the concepts of “consumer sustainable choices” and “consumer sustainability,” we discuss how conscious consumers can transform this cycle in the changing balance of power.

The Conceptual Framework of Sustainability

Although the concept of sustainability is often equated with environmentally friendly practices in the modern world, it is essentially a holistic approach that considers the long-term continuity of economic, social, and ecological systems together. The most frequently referenced definition of the concept is found in the 1987 United Nations World Commission on Environment and Development report, Our Common Future (Brundtland Report): “Meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

This definition shows that sustainability has a temporal dimension. Every production and consumption decision made today determines the resource allocation and quality of life of tomorrow. However, the fundamental tension here is that the modern economic system is built on continuous growth, which often means increased production and increased consumption. Sustainability, on the other hand, aims for long-term balance with limited resources. The contradiction between these two approaches has paved the way for concepts such as planned obsolescence and consumer sustainability.

Planned Obsolescence: A Designed Mechanism for Economic Continuity

Planned obsolescence is the deliberate limitation of a product’s lifespan during the production or design phase. The aim is not technical, but economic: to accelerate the sales cycle by ensuring the product is replaced more quickly.

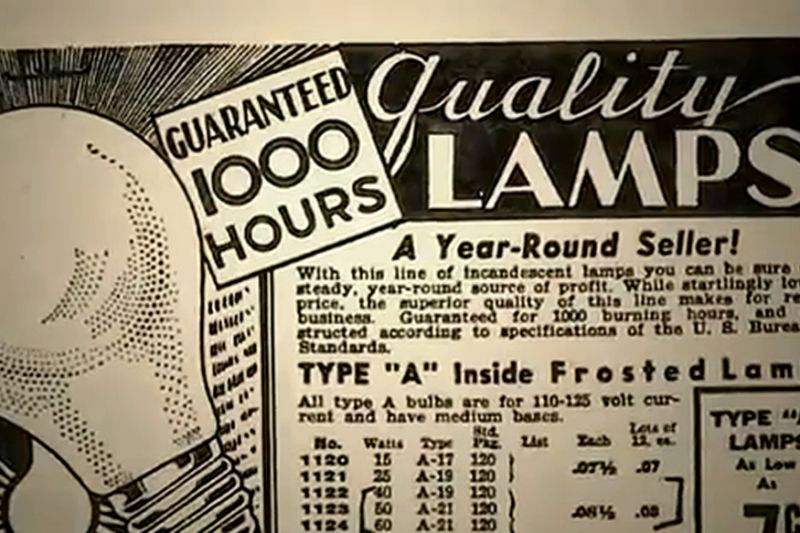

One early example of this strategy is the Phoebus Cartel, founded in 1924. Formed by major light bulb manufacturers in Europe and America, this cartel standardized the lifespan of incandescent lamps from approximately 2,500 hours to 1,000 hours. This decision stemmed not from technical necessity, but from a desire to increase sales volume. Planned obsolescence thus became institutionalized as a conscious strategy of industrial capitalism.

In the 1950s, industrial designer Brooks Stevens defined planned obsolescence as “creating in the consumer a desire to buy something a little newer, a little better, a little sooner.” This statement shows that planned obsolescence is not only about physical durability; it is also a psychological and cultural design strategy.

Today, planned obsolescence operates on three levels: technical (limiting the durability of the product), software-related (reducing update support for digital products), and psychological (making the product feel “old” through aesthetic and fashion cycles). This three-pronged mechanism ensures the self-reproduction of the economic system.

Polyester and Fast Fashion: The Material Policy of Short-Lived Design

One of the most visible areas of planned obsolescence is the textile sector. According to the Textile Exchange 2023 Materials Market Report, polyester is the most widely produced textile fiber worldwide, accounting for approximately 54% of total fiber production in 2022. This demonstrates the dominant role of synthetic fibers in production and the significant market share of polyester.

The reasons for choosing polyester are economic and structural: low cost, suitability for mass production, flexibility, and adaptability to rapid collection cycles. However, these advantages also fuel a culture of short-lived use. Low-weight and low-quality polyester products may lose their shape after a few washes; they quickly lose their aesthetic value. Although the product physically remains, its use value decreases.

Furthermore, polyester is petrochemical-based and causes the release of microplastics during washing. These microplastics enter the marine ecosystem, creating long-term environmental impacts. Thus, the short-life consumption model produces not only an economic but also an ecological burden.

It is estimated that approximately 92 million tons of textile waste are generated worldwide annually. This data clearly demonstrates the environmental cost of the shortened lifecycle designed for the textile industry.

Consumer Sustainability

A conceptual distinction needs to be made here. “Sustainable consumer choices” and “consumer sustainability” are not the same thing.

Sustainable consumer choices are the choices individuals make with an awareness of environmental and ethical responsibility: buying longer-lasting products, repairing, using second-hand items, consuming less.

Consumer sustainability, on the other hand, is the system’s self-sustainability strategy. This concept refers to the uninterrupted continuation of the consumption cycle for the continuity of the economic structure. Planned obsolescence is one of the tools of this strategy. Products are rapidly renewed, the consumer is included in the cycle, and economic continuity is ensured. This continuity is sometimes presented together with the discourse of sustainability; however, in practice, a divergence can occur between the sustainability of the system and the sustainability of the planet.

According to the United Nations Environment Programme’s 2022 report, approximately 400 million tons of plastic are produced worldwide annually. A significant portion of this production consists of single-use packaging. This model challenges ecological sustainability while maintaining economic sustainability.

Is the Balance of Power Shifting?

Digitalization, the democratization of access to information, and the increasing demand for transparency are transforming consumers from passive buyers into active participants capable of exerting pressure on the system. Policies like the European Union’s “right to repair” regulations aim to extend product lifecycles and limit planned obsolescence. These regulations demonstrate that consumer demand is finding institutional resonance.

Brands now need to be more visible regarding product lifecycle, carbon footprint, and supply chain transparency. This is because consumers are increasingly questioning not only the price but also the production process. This transformation shows that the system’s self-sustaining strategy is not absolute.

Reppatch’s approach rejects the idea of ”unavoidable waste” assumed by planned obsolescence. Upcycling questions the assumption that when a product’s economic life ends, its use value also ends. Incorporating used materials into a new design process redefines the product’s lifecycle.

This approach is not merely an environmental gesture; it is a critical position on the economic model. Extending product lifecycles, slowing down the rate of consumption, and making the user a part of the production process weakens the assumptions of planned obsolescence.

Ultimately, the issue is not simply about reducing consumption. The issue is what kind of sustainability is being pursued. Will the system prioritize its own continuity, or the continuity of the ecosystem and the social structure? The answer to this question is increasingly being shaped by consumer decisions.